Mercedes Sprinter

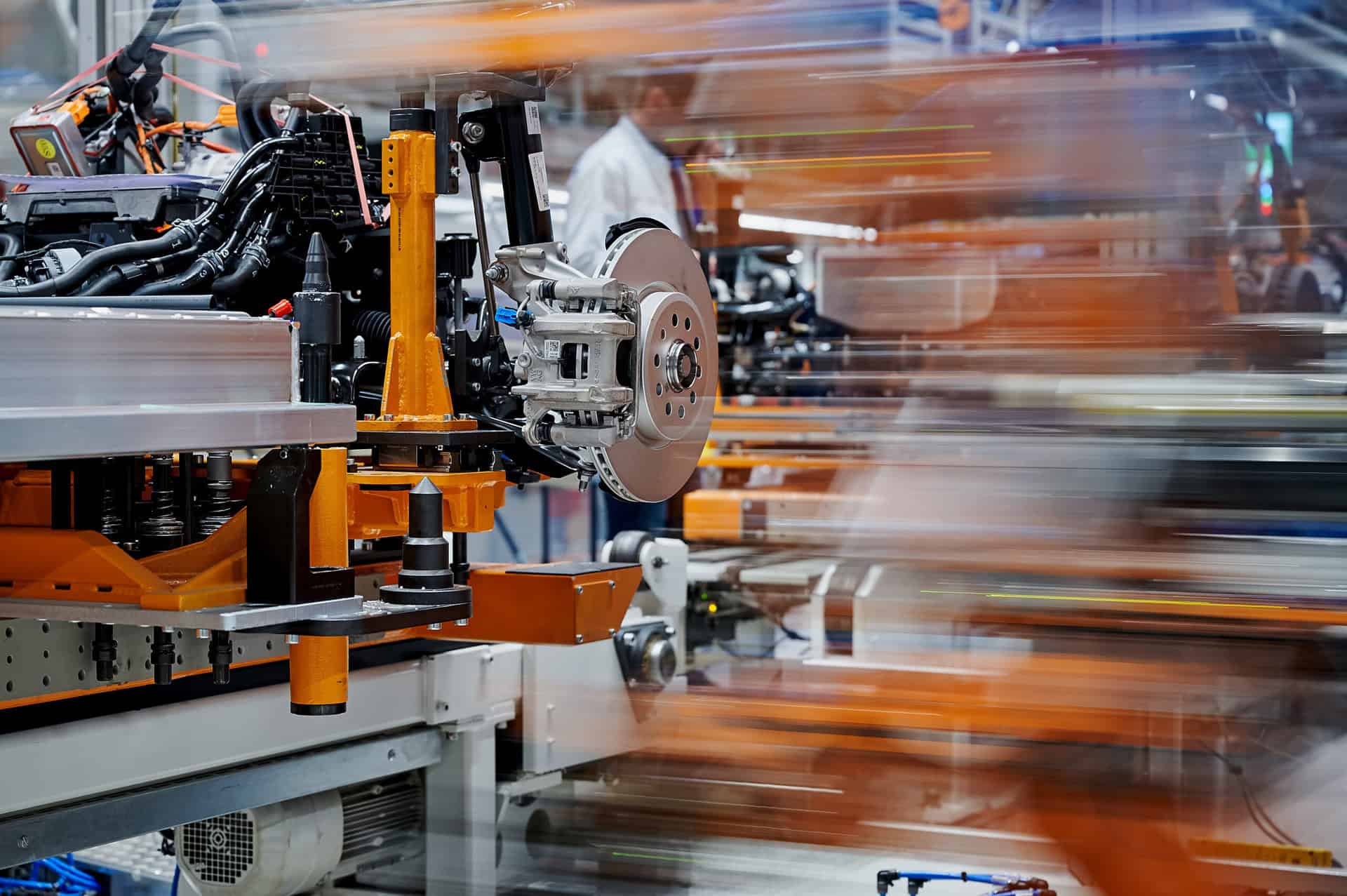

Integration of the eSprinter into the existing pre-assembly of major components and marriage

About the project

Hinter den Kulissen:

LeistungenThe following sub-areas were expanded for the integration:

Mechanism frame: To place the product parts on the existing mechanism frame, new holders had to be created in the area of the battery (centre tunnel) and rear axle. The result was a mixable frame that can be used for both combustion engines and battery-powered vehicles.

Marriage Beat 1: A camera system was integrated to check whether product parts have been placed correctly or whether folding positions on the mech frame have been executed correctly.

Marriage Beat 3: Two robots were integrated into the existing assembly beat, which take over the bolting of the battery and rear axle on the eSprinter, as well as bolting points on the combustion engine.

The conveyor system was overloaded because the eSprinter also brings higher weights onto the line.

Additional screwdriving technology has been integrated into the individual stations – extension of control technology.

Innovationen aus Herausforderungen geboren

besondere Aufgaben

-Timely completion of the assemblies for the conversion of the mech frame -Drive design for conveyor technology -Integration of the control technology for the robots in combination with a camera system (topics such as robot and camera calibration) -Sorting of the vehicles in the robot programmes -Teaching robots for different derivatives and wheelbases -High need for coordination throughout the entire project

Mach unsere nächsten Projekte zu deinen!

Stellenangebote

Du liebst spannende Herausforderungen und möchtest an Projekten wie diesen mitwirken? Schau dir unsere Stellenangebote an und werde Teil unseres Teams!

Unsere Stellenangebote