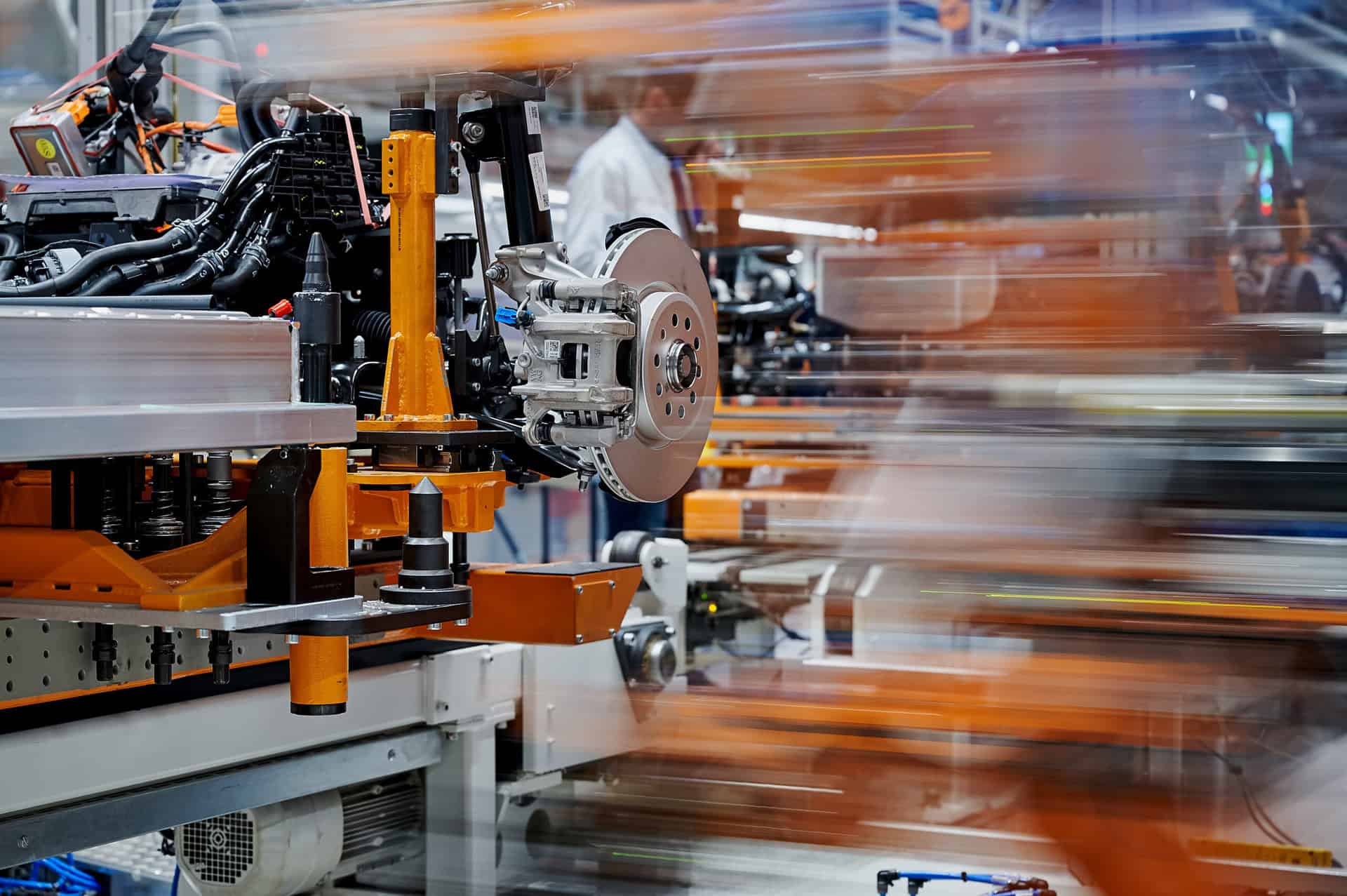

Mounting frames

Future models based on the MQB or MEB platform will have standardised chassis frames that are individually put together from a modular system and adapted to the respective brand, model and location requirements.

About the project

Hinter den Kulissen:

LeistungenProduction of 9,000 assembly frames with a total volume of approx. €90 million

Delivery to approx. 30 VW AG sites

Innovationen aus Herausforderungen geboren

besondere Aufgaben

MBN is to supply the frames described in the specifications in numerous variants and configurations, taking into account material price fluctuations, the purchase of a laser tracker system, all additional costs, confidentiality requirements, high manufacturing quality, quality assurance and documentation. Despite these requirements, a fixed price has been agreed.

Mach unsere nächsten Projekte zu deinen!

Stellenangebote

Du liebst spannende Herausforderungen und möchtest an Projekten wie diesen mitwirken? Schau dir unsere Stellenangebote an und werde Teil unseres Teams!

Unsere Stellenangebote